Pettinaroli's printing art

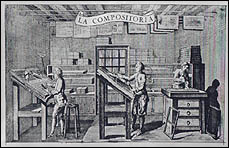

This is the initial phase. The print characters, made of melted lead and stored in drawers divided into numerous small compartments, are arranged manually to form the desired text. It seems incredible not to use the COMPUTER for such things, but certain characters such as the millerighe - which many of our customers call "your typeface" - and English italic, when printed with lead letterpress really do produce a completely different effect.

This is the initial phase. The print characters, made of melted lead and stored in drawers divided into numerous small compartments, are arranged manually to form the desired text. It seems incredible not to use the COMPUTER for such things, but certain characters such as the millerighe - which many of our customers call "your typeface" - and English italic, when printed with lead letterpress really do produce a completely different effect.

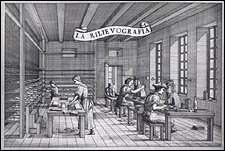

RELIEF PRINTING

This is the procedure used to produce embossed or relief print finishes and consists of 2 complex and artistic processes.

This is the procedure used to produce embossed or relief print finishes and consists of 2 complex and artistic processes.

The initial phase is the engraving, an art which amounts to a passion for those who perform it. The design is drawn and then engraved on a steel plate about 1 cm thick, after which it is finished entirely by hand. This procedure takes place in reverse, working from right to left so that when the plate is turned over for printing the text will appear correctly. There is no school where these processes can be learnt, and it is the craftsmen themselves who pass on the technique from one to another with masterful expertise. The resulting products are engraved steel plates which are small masterpieces in themselves, even before printing.

The second phase, no less important than the first, is the printing. The machines used are different from those used for letterpress

printing; these are machines specially designed for relief printing, and once again are manual or semiautomatic to ensure optimal results. The inks used are different too, enamels which once printed and dried give a slightly gloss effect. In fact true relief printing, performed in accordance with the original techniques is actually called enamel embossing (smaltorilievo).

This procedure is still used today, especially for visiting cards, writing paper, coats-of-arms and company logos. For an effect which

really does stand out.

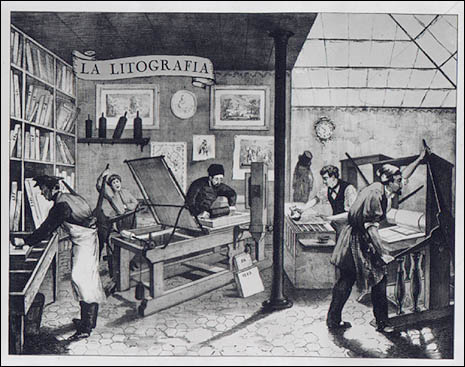

LITHOGRAPHY

This technique is difficult to perform, and even more difficult to understand. If you succeed in both, then the results are masterpieces: austerely elegant and not ostentatious, provoking the simple pleasure of holding something truly beautiful. If relief engravers are increasingly thin on the ground, lithographic engravers are like gold dust.

This technique is difficult to perform, and even more difficult to understand. If you succeed in both, then the results are masterpieces: austerely elegant and not ostentatious, provoking the simple pleasure of holding something truly beautiful. If relief engravers are increasingly thin on the ground, lithographic engravers are like gold dust.

Here too the technique demands reverse engraving, this time on limestone, most of which comes from the quarries of Bavaria, using

diamond tips of different widths to obtain broader or finer lines. Here the printing area is no higher than the non-printing area, the matrix is continually moistened during the pressing process, and the grease used to cover the lines of the design on the stone repels the water and attracts the ink.

At the moment we still have two lithograph engravers; when they go, who knows what will happen.

Lithographic printing produces particularly spectacular results in the realm of visiting cards and wedding invitations, where we really can speak of impressive "special effects".

BOOKBINDING

Everything that can be done with paper and related materials, such as canvas and leather, is carried out in our bookbinding department. In this field too our workmen, trained in specialist schools, are master craftsmen, since manual expertise is both a gift and something which is refined with experience.

Everything that can be done with paper and related materials, such as canvas and leather, is carried out in our bookbinding department. In this field too our workmen, trained in specialist schools, are master craftsmen, since manual expertise is both a gift and something which is refined with experience.

And so we succeed in producing truly splendid objects such as photograph albums, address books, diaries etc. where nothing - from the choice of hand-made papers, the matching materials, the gold printing etc. - is left to chance.

There are no products in this section